Design of Underground Wells

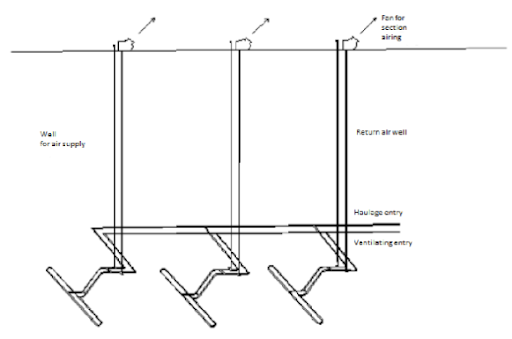

Wells for the Airing of the Mining Sections

Oil mines on the Yaregsky field were built for crude oil production without thermal influence, instead using various mining methods.

Upon transition to thermal and mining technology, there were problems with tracking the thermal mode on remote blocks.

To solve this problem, wells of section airing have been constructed for the airing out of remote blocks while not impacting the conditions of the surrounding blocks.

At the same time, the block is isolated from all-mine ventilation.

Design of Underground Wells

Driving of the Mine Workings with Drilling and Blasting Method

Drilling and blasting method (DBM)

Drilling-and-blasting way (BVS)

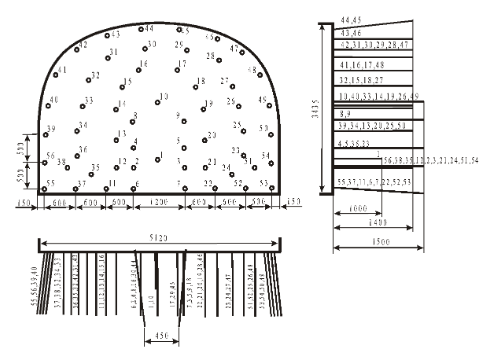

According to a certain scheme, blast holes are drilled in the surface in which the explosive is placed. The blasts occur with a delay in milliseconds, so that rock outbursts could be on a development axis.

Temporary roof supports are installed to provide safe stays for drifters in the earth’s surface. Prior to metal flexible roof support installation, which are made of a special interchangeable profile, sliding consoles were used as temporary roof supports. For the prevention of falling small pieces of rock, the open space of a roof between consoles is blocked with wood roofing.

After the installation of temporary roof supports, cleaning of the beaten-off pieces is made. For this purpose, in mines rock loaders are used (for example, PPN1S).

On average, the face advances for 0,9 m in one operation. The rate of driving with DBM in oil-saturated sandstone is 240 m/year.

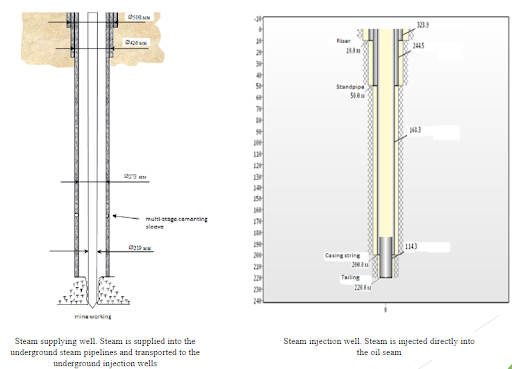

Design of UndergroDesigns of the Surface Injection and Steam Supplying Wellsund Wells

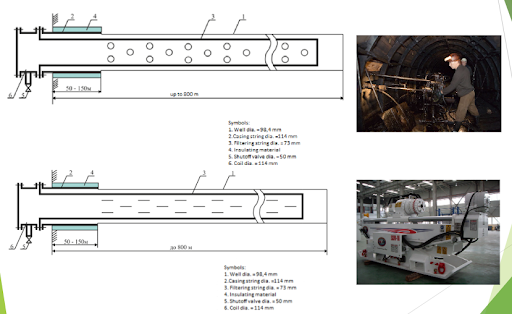

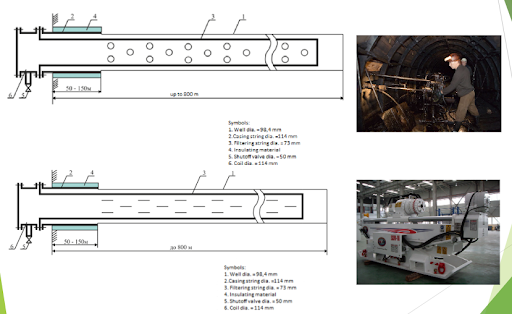

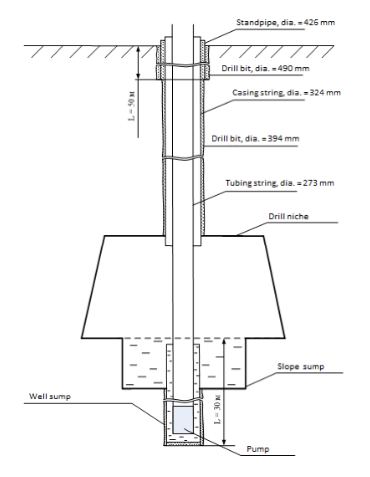

Wells for Pumping Fluid Off from the Sumps

To be treated, collected oil must be transferred to the surface via pumps, and further through the pipelines, it is transported to the oil treatment unit for processing.

These pumping-off wells are additionally useful as they reduce the heat of the pipelines, which creates a safer environment for the mine working units.

Driving of mine workings with a mechanized method (Entry driver KP-21)

Entry drivers are used in areas with weak rocks or crumbling foundations to place horizontal and raised (up to 35o) mine workings. The use of entry drivers is safer and more effective than the Drilling and Blasting method, and they do not impact the integrity of the surrounding rocks.

An Entry driver can drive mine workings of arch, trapezoid, and rectangular shapes with sizes from 2,3 m to 4,5 m in height and from 3,6 m to 6,5 m in width. They’re also able to cut rocks of uniaxial compression σсж ≤ 100 MPas and an abrasion index of up to 15 mg according to L.I. Baron and A.V. Kuznetsov.

The executor of the Entry driver has an arrow-shaped form, and it is equipped with a longitudinal axial conic cutting bit, telescopic sliding boom, and a hydraulic clutch of the sliding part of the boom, and a supply system of water to bit cutters to decrease of dust formation and ensuring explosion protection.

The running gear of the Entry driver represents caterpillar trucks with a separate hydraulic actuator on each caterpillar.

The feeding mechanism has separate, kinematically independent hydraulic actuators and controls on each heaping element. Tramming hydraulic actuators and the feeding mechanisms allow the Entry driver to work in the watered faces.

The Entry driver’s conveyor is a flight one and made a turning tail section for loading cut-off rock on the face conveyor.

The Entry driver has devices for connection of the additional hydraulic equipment (a hydraulic drill rig, hydraulic tools, etc.).

Roof support jack has a blocking device, which makes work on roof support installation convenient and safe.

The advantage of the Entry driver’s driving of mine workings is that with this method destruction of the massif is carried out along with loading of the cut off rock formation on the overloader. Thus an increase in the speed of driving is provided.

The Entry driver KP-21 is used when driving in the tuffite horizon. The speed of driving is 530 m/year. On oil saturated sandstone performance indicators of KP-21 are low.