Thermal Mining Development

In 1937, I.N. Strizhov proposed applying Thermal Formation Stimulation to change the conditions of the oil mines in the hopes of improving extraction efforts. However, poor technical application and lack of experience in predicting the impact of the thermal conditions in the mines made Thermal Formation Stimulation less than successful.

Though it was not continued at that time, it has not been forgotten as a possibility. Rather, in the late 1960s, further theoretical and laboratory work was done to consider possible effective applications in oil mines.

In 1968, further work was done in the development of Steam Formation Stimulation. Positive results were achieved for the first time, which led to a shift in the industry to the application of Steam Formation Stimulation in present oil mines in 1972. This method was recognized as the primary method for the thermal mining of crude oil production and was an invention recognized and patented in the USA, Canada, Venezuela, and Japan. Involved scientists included P.G. Voronin, E.I. Gurov, V.S. Sukrushev, V.S. Zubkov, N.I. Melnichuk, G.G. Miller, V.G. Verty, V.P. Tabakov, V.N. Mishakov, and L.M. Ruzin.

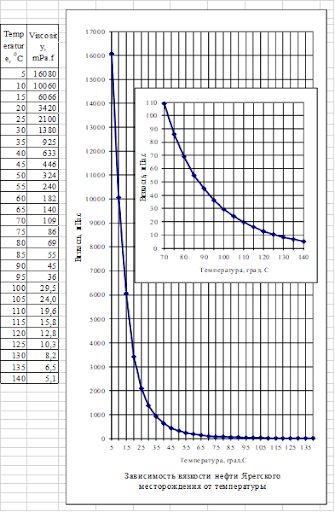

Thermal Mining consisted of warming up a layer of crude oil and decreasing its viscosity, which would in turn increase its mobility and extractability. At a temperature of 700C, the viscosity is 109 MPa.s, and at a temperature of 1000C, it is 30 MPa.s.

At the time, there was no practical experience to anticipate the impact of heat on the outer seam of the oil mines. Therefore, for the implementation of the Thermal Mining method to be effective, multiple theoretical and practical problems needed to be solved first.

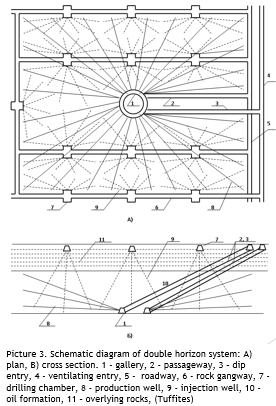

Several systems for the position of wells in the seam were developed for the implementation of the Thermal Mining method, including the Double Horizon System, the Single Horizon System, an Underground-to-Surface system, and the potential combination of these systems with one another.

Oil production was made via dense systems of horizontal and slow uprising underground wells, which were drilled in the mines and driven from the lower segments of the production formation, referred to as the Production Gallery. These three systems differ only in the arrangement of their injection wells.

Double Horizon System of Thermal Mining Development

The Double Horizon System steam injection is conducted through a dense pattern of underground injection wells drilled in the mine workings (or rock gangways), which are established along the oil seam. Steam is pumped through a system of underground steam lines from the steam supply tank to these underground injection wells, forcing the hot air from the surface into the mine workings.

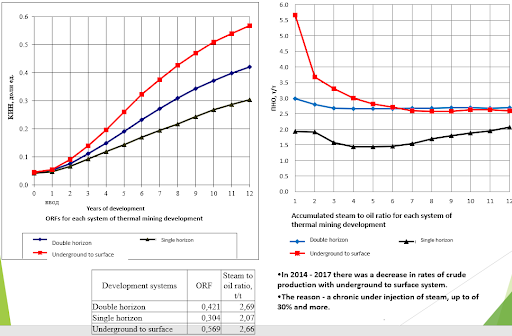

The development of the blocks using the Double Horizon System have performed at a high technological rate. The average ORF in the abandoned blocks in 0,54 with a steam-to-oil ratio of 2,68 t/t. From 1972 to 2007, the Double Horizon System has been utilized in 90 to 95% of mine areas in which the operation has already been established.

The Double Horizon System differs in its high coefficient of formation coverage with thermal influence, but it also demands a large volume of driven mine workings at 240 m/hectare. In addition to the mine workings, its difficult configuration dictates a complex ventilation system that makes troubleshooting and maintenance more difficult. Also, there are additional thermal emissions in the underground air because of these steam lines that are fed from above the group.

With the increasing volume of mine excavation projects, the Double Horizon System likely is not a sustainable solution and will not continue to be used.

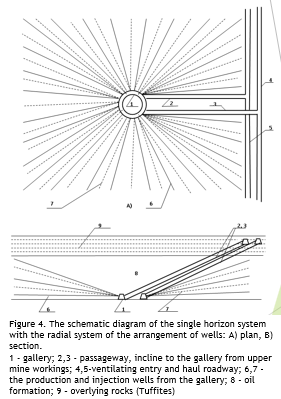

Single Horizon System of Thermal Mining Development

The Single Horizon System is a more direct process as steam is injected through the underground wells directly from the production gallery. It does not require the excavation of rock gangways like the Double Horizon System, which allows the excavation process to be decreased by 2.5 to 4 times.

The Single Horizon System does not allow for as much steam to be pumped through the underground wells from the production gallery, and the greatest temperature and reach occurs on the oil seam near the gallery, which disrupts the thermal conditions in the mine workings. Through this method, it is necessary to reduce the rates of the steam injection, because that will decrease the rate at which the oil seam is heated, which will also increase the time in development of the blocks and reduce the ORF.

With the Single Horizon System, the ORF does not exceed 0.4, but the steam-to-oil ratio is lower than with the other systems, averaging about 2 t/t. In the field, the Single Horizon System is applied on a limited scale, impacting only about 5% of the surface areas that are under development.

The Single Horizon System became the leader of surface technology in thermogravitational drainage systems, specific to the oil seam (TGDP or SAGD).

In 1977, representatives of the Canadian firm “AOSTRA” visited Yarega for a field study, and as a result, the first mine was built on the Atabask field where a Single Horizon System had been established previously. Unlike the Yarega productive depositi, the productive formation of the Atabask deposit was located on anhydrous limestones, and the mine workings had been excavated under the seam at a distance of 15 to 20 meters. This allowed for the issues with thermal conditions to be solved, and further work by AOSTRA has determined the possibility of bringing the wellheads of underground wells to the surface for the SAGD technology to truly become a reality.

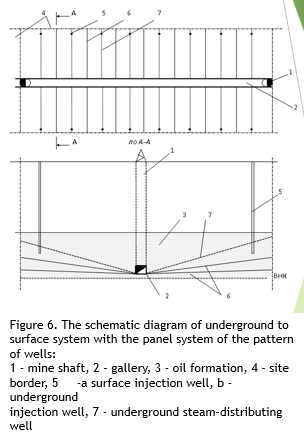

Underground-to-Surface System of Thermal Development

From 1996 to 1997, the Underground-to-Surface System was developed. Its fundamental difference from the other systems consisted of the pumping of steam into the seam through surface wells to the border of the site under development. For the distribution of steam across the seam to the bottoms of the injection wells, underground wells are drilled at the beginning of the process and are referred to as steam-distributing wells. The steam from the injection wells is sent through underground steam-distributing wells and spread across the oil seam. As a result, the horizontal well is cloned, but the cost of its construction is 8 to 10 times lower than the building of horizontal wells from the surface.

The thermal front is distributed from the border of the block under development to the extracting gallery. This allows the rate of steam injection to increase by 2 to 3 times, for the pumping pressure to increase to 1,6 MPas, and for the temperature to rise to 200 degrees celsius. With the former systems, the steam injection pressure rarely exceeded 0,2 to 0,4 MPas, and the temperature did not rise about 120 to 140 degrees celsius. The viscosity of the oil directly depended on its temperature, which is able to rise much higher through this new system.

During the initial development of the Underground-to-Surface System, steam was injected at the highest possible rate, which led to an intense warming up of the seam. This allowed the team to determine the highest possible rates of crude oil production, as well as the highest achievable steam-to-oil ratio.

Compared to other systems, the rate of oil production has grown by 1.4 to 1.9 times, and an average of 4 to 5% per year, and the maximum rates have reached 9 to 10%. In 2017, crude oil production with the Underground-to-Surface System exceeded 90% of all oil production.

With underground wells reaching 300 meters, mine workings for Single Horizon and Undergrand-to-Surface Systems makes up 92 m/hectare with radial, and 57 m/hectare with a panel arrangement of underground wells. With wells at 800 meters, the Systems make up to 28 m/hectare. The Double Horizon System would be 240 m/hectare.

Implementation of the Underground-to-Surface System has allowed excavation processes to reduce by 8.6 times the mine workings and 8,3 times the volume of underground drilling.

Heat Distribution of Single Horizon and Underground-to-Surface Systems

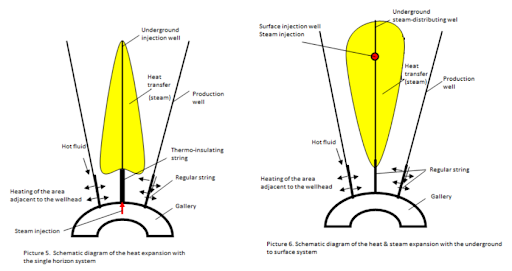

Below are schematic diagrams of the distribution of heat using the Single Horizon and the Underground-to-Surface Systems.

Please note that these schematics are incredibly similar, with the primary differences being the use of Thermo-insulating Thread or Regular Thread, as well as the point from which steam is injected either above or below ground.

Saturated steam pressure of 1,6 MPa with a corresponding temperature of 201 degrees celsius is the value limit for thermal mining development in the Yaregsky field. After 207 degrees celsius is reached, distillation (or cracking) of the oil in the seam occurs, which is detrimental to continued mining development and crude oil production.

Development Indicators of the Systems of Thermal Mining Development

Using 12 years’ worth of data, the following pair of charts demonstrate the Oil Recovery Factor (ORF) and the accumulated steam-to-oil ratio, based on the Single, Horizon, or Underground-to-Surface System used.

The Scheme of the Oil Mine and Crude Oil Production on the Yarega Field of 1932 to 2017

The following pair of charts depict the oil mining framework at the Yarega field, including neighboring establishments, as well as a chart that shows the depleted underground cruel oil and increasing thermal mining efforts.

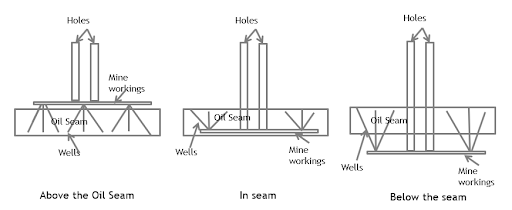

Disposition of the Oil Mine and Mine Workings Relative to the Oil Formation

In the above picture, three mine working systems have been depicted. Note specifically the differences in the positionings and direction of the wells, the placement of the mine workings, and the depth of the holes.

The Above the Seam method is considered to be the worst, as the gravitational energy is not utilized in the extraction of the oil. Similarly, the In Seam method does not utilize gravitational energy as well as possible, and big thermal emissions from the heated seam were experienced. Additional mining structures also could not be placed under the seam at a later date because of the abundance of water that was collected beneath in the process. Under the Seam was considered to be the best of the mining arrangements. Gravitational energy was used effectively, and there were minimal thermal emissions.

In the structuring of mines, the formation will be more successful depending on its use of gravitational energy and its proximity to the oil seam itself, which benefits underground formations. Similarly, the cost significantly diminishes in the formation of underground wells, making them the more logical choice.