Sites for Injection of the Extracted Associated Water

One of the problems of developing the Yaregsky deposit is getting rid of the water that is being extracted. Until 2016, the extracted associated water had been pumped into the sites for the mine water injection, adjacent to the field, or discharged into developed blocks. Taking into account the connection through the aquifer, the discharged waters again came into the operating blocks.

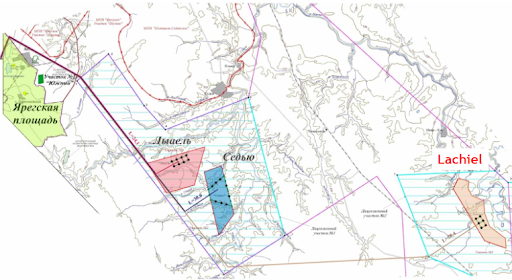

In 2016, a water treatment plant with a capacity of 700 t / h (VPU-700) was launched, which treated extracted associated water to boiler quality. In 2016, experimental/development work began the pumping of surpluses of associated water to the Lachiel site, located at a distance of 58 km from the field.

Planned Experimental-Industrial Works

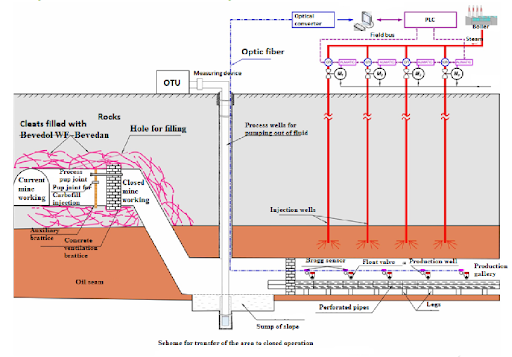

- Development of the work automation control system of underground wells and management of the process of formation stimulation through surface wells and carrying out trial tests.

- Trial works on testing of the closed (deserted/unmanned) operation of mining sites.

- Trial works on testing the combined system of thermal mining development.

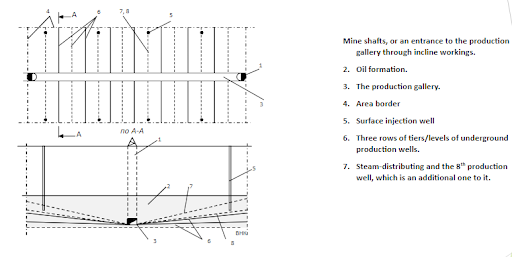

- Trial works on testing of three-row underground and surface systems of thermal mining development.

- Continuation of trial works on the mechanized driving of mine workings.

- Experimental industrial works on geological studying of the site of Laciel for injection of waters.

- Trial works on scrubbing the Eifelian horizon with the subsequent oil recovery and production of a titanic concentrate.

- Design of the mini-mine.

The system of Automation for the Operation of Blocks with the Thermal Mining Method

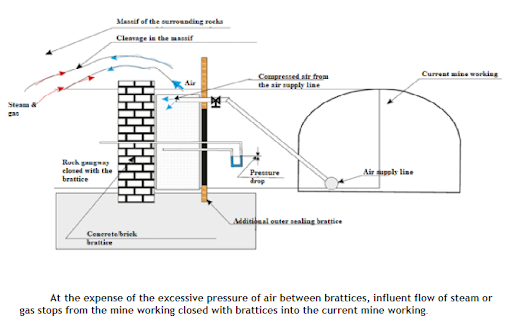

Method of Isolation of Mineworking (Airlock)

Triple Row System

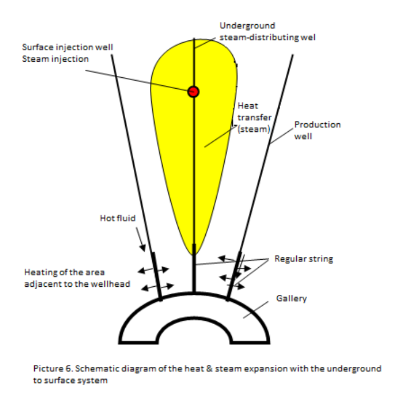

Studies of the Underground to Surface System has shown that it is possible to inject the required steam in smaller quantities through of injection wells. Therefore, when three rows of underground production are located between the injection sight and the corresponding steam-distributing wells, the process can be tested. Studies have yielded positive results. It has reduced the construction of surface injection wells by 20%.

Combined System of Thermal Mining Development (Underground to Surface and Single Horizon Processes)

The rate of oil production depends on the rate of energy (heat) input into the reservoir. At the initial stage of development, steam is pumped through a surface injection well and through underground wells. This increases the rate of formation heating. After the beginning of significant heat releases into the mine workings, injection into the underground well is stopped.