Method of Calculation of Indicators of Thermal Mining Development

Permit to use of the technique: Federal Agency on Mineral Resources (The letter No. EK-03-31/6843 of 23.06.2015)

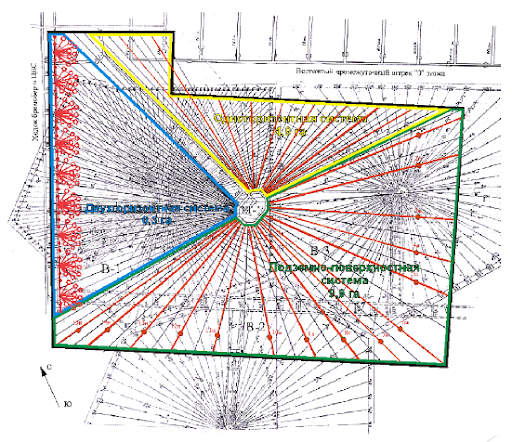

Arrangement of Old and New Wells in the Block 1T-1

Methods for Calculating Process Indicators: Thermal Mining Development

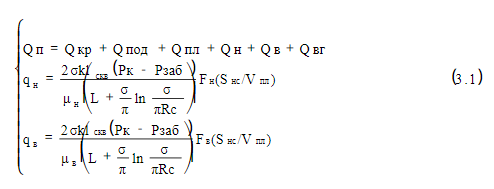

Equation 1 is the heat balance equation for the formation.

Equation 2 is the single-stage filtration equation for oil (Dupuit equation).

Equation 3 is the single-stage filtration equation for water (Dupuit equation).

Note. The process of displacement of high-viscosity oil in the Yaregskoye field with a super dense pattern of underground wells does not work out. Water and steam always find the filtration channels in underground wells and do not perform a displacing action.

The mechanism of oil production is determined mainly by pulling oil from the pore matrix due to a sharp decrease in pressure during the condensation of steam.

This takes into account the correlating functions Fn and Fb, which are determined by the development history.

When pumping hot water, even with a temperature higher than that of steam, there is no condensation effect and no oil extraction from the pore matrix. Therefore, the rate of oil production is lower.

Properties of Saturated Steam

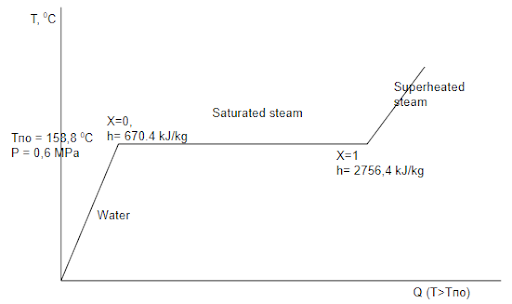

Example for the pressure P = 0,6 MPas.

The beginning of phase change of water to steam (boiling) for each pressure occurs at strictly a certain temperature. For example, for pressure of 0,1 MPas (1 atm.) steaming temperature Тпо = 100 0С, for pressure of 0,6 MPas (6 atm.) Тпо = 158,8 0С

After achievement of steaming temperature, maintaining of pressure and heat transmission, steam generation process begins. At the same time, the temperature does not change. All heat goes for steam generation process. At the same time the dryness of steam changes.

The dryness of steam (X) changes from X = 0 which is the beginning of steam generation, to X = 1 when all water transform into steam. Further when steam with higher temperature comes than that of the steaming temperature, the steam becomes superheated with preservation of pressure.

Depending on dryness (X) enthalpy of steam changes from h = 670.4 kJ/kg at X =0 to h = 2756,4 kJ/kg at X = 1, or by 4,1 times.

Note. For injection in the seam, saturated steam with dryness of X = 0,7 – 0,95 is used. Injection of superheated steam is not recommended. As for its production, requirements to quality of water treatment become significantly tougher, and this means expenses. The superheated steam is used in production with circulating water supply, for example on thermal and nuclear power plants.