Surface Development without Formation Stimulation

Crude oil production was first attempted in 1932 and would continue to be perfected through 1943, by means of surface well access, without additional formation stimulation. The first two sites were a total of 43,4 hectares (or 0.43 square kilometers per hectare), and their wells were drilled in a triangular pattern with a spacing of 75 to 100 meters between them.

For 10 to 12 years, the development of the Oil Recovery Factor (ORF) had only recovered 0,017 units of oil, as oil extraction from the surface without formation stimulation was unprofitable.

In 1934, geologist A.V. Kulevsky suggested treating the surface formation with hot water. Early laboratory tests showed encouraging results with the use of hot water, but application proved to be another matter. A weak technical base did not allow for the implementation of thermal formation on the oil field, resulting in no improved stimulation.

The Ukhta System of Mining Development

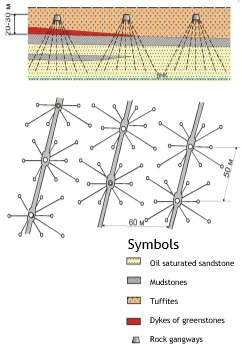

From 1939 to 1954, mine development was conducted using the Ukhta System, which involved shifting rock formations 20 to 30 meters above the natural formation, every 50 to 60 meters. Mine excavations stretched 200 to 300 meters per hectare.

The seam was expanded with a dense pattern of wells, spaced out every 12 to 15 meters, and cut into the shifted rock formations. The depth of the wells was 40 to 60 meters deep and drilled in clusters, with 10 to 15 wells existing in each cluster. It was the first ever cluster drilling of oil wells.

The drilling of underground wells was made with the use of Craelius Systems and the underground drilling rig the “Ukhtinets” developed in the early 1950s. These machines could drill underground wells that were less than 100 meters long.

The development of the oil extraction was conducted on a dissolved gas drive. The prepared sites could be worked out of for 1.5 to 2 years, and the ORF made 0,04 to 0,06 units of oil with this method.

Mine Development without Formation Stimulation

Geologists I.N. Strizhov and Nikolay Tikhonovich, mine constructors P.Z. Zvyagin and I.S. Novoseltev, and other specialists in the Ukhta Pech Trust studied mine development of oil deposits in France (the Peshelbronn Field) and Germany (the Bitse Oil Field) before presenting the idea at the Yarega Oil Field. Based on their research, the group proposed attempting this method of development at the Yaregsky field.

The new mining project was approved, and on June 9, 1937, the picket, which indicated the location of the mouth of the first mining shaft, was put into position. After more than two years of construction and mining, the first oil was extracted in August 1939.

Unlike the inconsistent results of administering hot water to an open seam, all of the technological processes of crude oil production can be applied directly to the open seam and stimulate more oil extraction. Counter-pressure from a fluid head into the wells is almost completely eliminated, allowing the available formation energy to be used to its full capacity.

Development of oil extraction was conducted in the mines using two systems: the Ukhta System (1939 – 1954) and the Dip Entry Well System (1955 – 1972).

The Dip Entry Well System for Mine Development

In 1954, the underground drilling rig, the PBS-2T, was developed and capable of drilling horizontal underground wells of up to 300 meters deep. The machine was manufactured by the Yaregsky Petromine Management and the Ukhta Mechanical Plant.

In 1970, the PBS-2T was awarded a gold medal at the World Fair in Brussels and was in operation for more than 50 years.

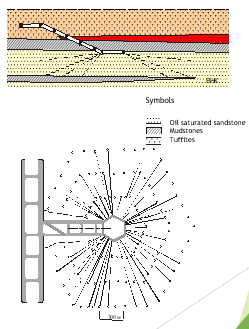

The collective experience proved that oil could be extracted by driving above the seam as well as indirectly into it. As a result, the Dip Entry Well System was developed.

The Dip Entry method involved entering the formation at two separate points and moving horizontally toward each other, parallel to the surface, before meeting at a point in the upper part of the formation. It was from this point that the circular extracting area was created, and in this area, a dense pattern of slow incline wells was drilled up to 300 meters deep. As a result, an area of 10 to 12 hectares was created, with 200 to 250 wells drilled at several tiers in the area.

The implementation of the Dip Entry Well System allowed for fewer excavation sites, minimizing mine production by up to three times. In conjunction, ORF was still used at the higher level of 0,04 to 0,06, where a higher viscosity of oil could be extracted.